Building a 60ft sailing boat from recycled plastic waste - an engineers perspective.

“What you want to do is impossible!” “You don’t know what you get yourself into.” “This boat will sink immediately!” These are comments that I hear often from my engineering colleagues. But their doubt gives me all the more reason to meet this challenge.

Flipflopi is attempting to do something that nobody has yet done. Such a daring initiative should not stop because we don't know enough. After all.. isn’t it us, Engineers, who strive to always seek deeper and beyond, develop further and create solutions?!

When I first heard about the Flipflopi dhow, a traditional sailing boat to be built from a ‘new’ material, recycled plastic, with old techniques, I knew that there were some tough challenges to be solved.

Traditional ways of building don’t involve designing an object in its entirety (whether it’s a table or a boat). Objects around us come to being after a long succession of incremental improvements. Stuff that works is replicated in the next generations, things that don’t, aren’t.

We want our boat to be replicable. Local ‘fundis’, the traditional builders, can replicate our way of working with this new material and even explore new ways to build whatever they know how to build: doors, tables or houses. For this to happen, the new material should be “designed” to be as similar as possible to wood. And since it is new, we can also use its unique properties to add other qualities, or ways of working with it.

How are we doing this?

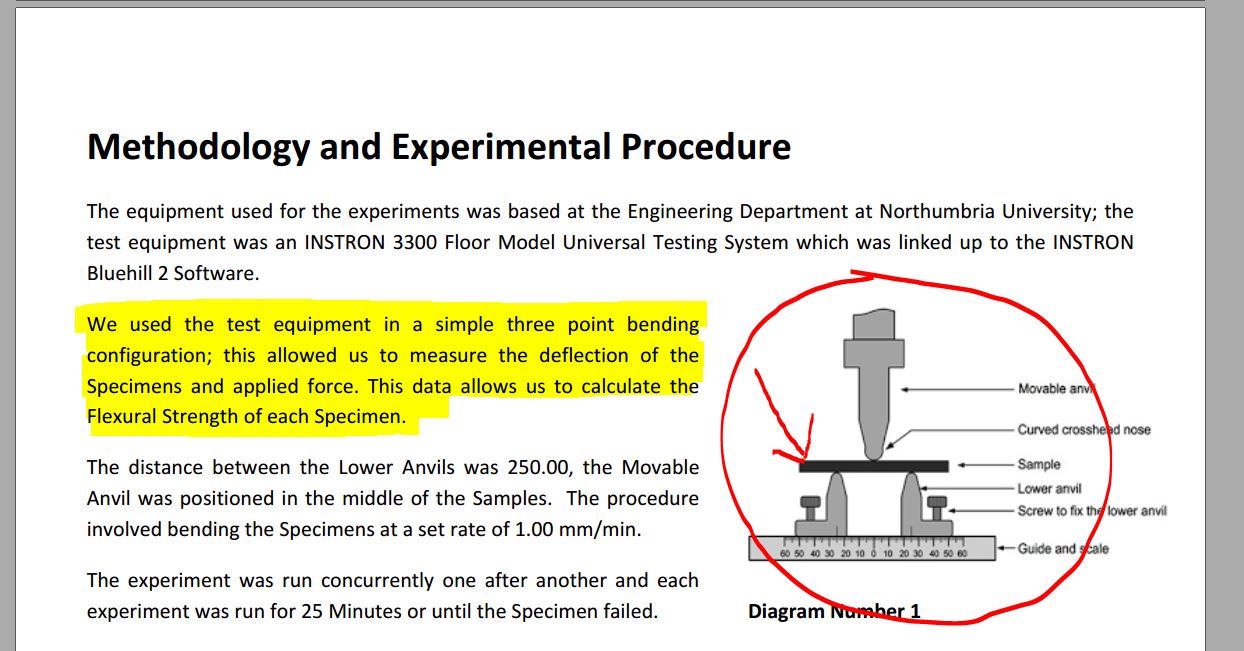

We produce many samples and we test and compare them under controlled conditions. This was undertaken at Northumbria University in the UK under the guidance of Simon Scott-Harden. His expertise helped us form a sound testing methodology, and his advise and research has been critical in getting the optimal strength qualities from our recycled plastic materials.

Simons testing allows us to evaluate which material mixture and processing will work for which condition. Just as there are different sorts of wood used for different products, we are developing different recycled plastic mixtures that offer us different properties. Light and strong, or hard and heavy.

We want to prove that this new material, made of waste, can be of value, can be strong and beautiful and that it can be used by those that have few resources but great ambitions.

I’d say, the tougher the challenge, the more rewarding is the success!

Leonard